- Ichalkaranji, Kolhapur, Maharashtra

- GST NO. : 27CNCPS2469E1ZT

- +91-9766536899, +91-7776971098

Universal Testing Machine

For more details please click on the links given below

MOQ : 1 Set(s)

| Business Type | Manufacturer, Exporter, Supplier |

| Machine Type | Universal Testing Machine |

| Automatic Grade | Automatic |

| Application | Testing |

| Color | Available In Many Colour |

| Condition | New |

| Power | Electric |

Preferred Buyer From

| Location | Worldwide |

SSS Make Hydraulic Grip Front Loading Computerized Universal Testing Machine is designed for testing metals and other materials under tension, compression bending, transverse and shear loads. Hardness test on metals can also be conducted.

Principal of Operation :

- Operation of the machines is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The hydraulic system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces. Load is applied by a hydrostatically lubricated ram.

- Main cylinder pressure is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The cylinder of the dynamometer is also of self-lubricating design. The load transmitted to the cylinder of the dynamometer is transferred through a lever system to a pendulum. Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autographic recorder.

- The deflection of the pendulum represent the absolute load applied on the test specimen. Return movement of the pendulum is effectively damped to absorb energy in the event of sudden breakage of a specimen.

Salient Features :

- Open type cross head

- Hydraulic wedge action grips

- Long test stroke and dual test space

- Loading accuracy as high as ± 1%

- Straining at variable speeds to suit a wide range of materials.

- Printer & PC graphs enable study the behaviour of the material.

- Motor driven threaded columns for quick effortless adjustment of lower cross-head-to facilitate rapid fixing of test specimen.

- Simplicity in reading because of digital readouts.

- Wide range of standard and special accessories.

- Easy change from plain to threaded and screwed specimens.

- Large effective clearance between columns enables testing of standards specimens as well as structures.

- Simple controls for ease of operation.

- Robust straining frame of an extremely rigid construction.

- Safe operation ensured by means of safety devices.

- Fully enclosed and protected pressure transducer.

- RS 232 serial port to transfer data to computer for analysis/storage evaluation etc.

- Manual control & release valve operation.

- Load Capacity : 100 kN, 200 kN, 400 kN, 600 kN, 1000 kN, 1200 kN and 1500 kN.

Optional :

- Servo controlled Motorized Valve incorporating of control modes - Standard manual control, Load rate control, Elongation rate control, Load hold mode, Auto start & initial valve open start.

NOTE : DUE TO CONSTANT R&D SPECIFICATION AND FEATURES ARE SUBJECT TO CHANGE WITHOUT NOTICE.

MOQ : 1 Set(s)

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Automatic |

| Power | 1-6 Kw |

| Application | Testing |

| Voltage | 380V, 220V |

| Warranty | 1 Year |

| Country of Origin | India |

| Pack Type | Wooden Box |

| Port | mumbai |

Preferred Buyer From

| Location | Worldwide |

Features :

We are a renowned Manufacturer and Exporter of Computerised Universal Testing Machine based in India. Designed to precision, the Universal Testing Machine offered by us is widely used for testing purposes in varied processes. Made from the best quality raw materials, our Universal Testing Machine possesses reliability and durability. Further, the clients can avail from us, the quality-tested Universal Testing Machine at very reasonable prices in the markets.

Hydraulic Controls

Hand operated wheels are used to control the flow to and from the hydraulic cylinder. The regulation of the oil flow is infinitely variable incorporated in the hydraulic system is a regulating valve. Which maintains a practically constant rate of piston movement. Control by this valve allows extensometer readings to be taken.

Electronic Control Panel

The electronic control panel is built using 8085 microprocessor which incorporates state of the art technology with following features :

- Front panel membrane type key board for test setup.

- 7 seg digital display of load displacement / extension. Printer port interface

- Serial port for communication with Pc.

- Optional add-on facility for electronic extensometers & electronic load pacer.

- Storage of important parameters such as peak load, displacement at peak load & maximum displacement alter test.

- Period selection to take care of initial slippage

Serial Communication & Software Package On PC

The SSS-UTM(E) series control panel can be hooked to any PC using RS-232 communication port. offers different exhaustive application. Window based software packages on PC to enable the user to effectively evaluate different parameters.

The features include :

- User friendly main menu with pop up menus prompt messages and help windows.

- Extensive graphics on screen for curve plotting, magnification and zooming.

- Evaluation of wide range of user selectable parameters such as young's modulus. yield stress. proof stress etc.

- Advanced file handling for data storage. Printout option for reports. data and graph etc.

- Optional software package for statistical evaluation.

Accuracy and Calibration

All Computerised Universal Testing Machines are closely controlled for sensitivity. accuracy and calibration during every stage of manufacture. Every machine is then calibrated over each of its measuring ranges in accordance with the procedure laid down in British Standards 1610: part 1: 1992 and 10: 1828:Part 1: 1991.Below 20% of the selected range. the maximum permissible error is 0.2%ofthe full load reading.

NOTE : DUE TO CONSTANT R&D SPECIFICATION AND FEATURES ARE SUBJECT TO CHANGE WITHOUT NOTICE.

MOQ : 1 Set(s)

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Industrial |

| Color | Multicolor |

| Country of Origin | India |

| Condition | New |

| Power | Electric |

| Warranty | 1 Year |

| Size | Standard |

Preferred Buyer From

| Location | Worldwide |

SSS Make Analog Cum Computerised Universal Testing Machine is designed for testing metals and other materials under tension, compression bending, transverse and shear loads. Hardness test on metals can also be conducted.

Principal of Operation

Operation of the machines is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The hydraulic system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces. Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The cylinder of the dynamometer is also of self-lubricating design. The load transmitted to the cylinder of the dynamometer is transferred through a lever system to a pendulum. Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autographic recorder. The deflection of the pendulum represent the absolute load applied on the test specimen. Return movement of the pendulum is effectively damped to absorb energy in the event of sudden breakage of a specimen.

Electronic Control Panel

- The electronic control panel is built using microprocessor which incorporates state of the art technology with following features :

- Front panel membrane type key board for test setup.

- 7 seg digital display of load displacement / extension. Printer port interface

- Serial port for communication with Pc.

- Optional add-on facility for electronic extensometers & electronic load pacer

- Storage of important parameters such as peak load, displacement at peak load & maximum displacement alter test.

- Period selection to take care of initial slippage

Serial Communication & Software Package On PC

The SSS-UTM(M)(E) series control panel can be hooked to any PC using RS-232 communication port. offers different exhaustive application. Window based software packages on PC to enable the user to effectively evaluate different parameters.

The features include :

- User friendly main menu with pop up menus prompt messages and help windows.

- Extensive graphics on screen for curve plotting, magnification and zooming.

- Evaluation of wide range of user selectable parameters such as young's modulus. yield stress. proof stress etc.

- Advanced file handling for data storage. Printout option for reports. data and graph etc.

- Optional software package for statistical evaluation.

NOTE : DUE TO CONSTANT R&D SPECIFICATION AND FEATURES ARE SUBJECT TO CHANGE WITHOUT NOTICE.

MOQ : 1 Set(s)

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Manual, Automatic |

| Power | 1 To 5 Kw |

| Application | Industrial |

| Voltage | 380V, 220V |

| Warranty | 1 Year |

| Country of Origin | India |

| Download |

| Port | Mumbai |

Preferred Buyer From

| Location | Worldwide |

SSS Make Universal Testing Machine is designed for testing metals and other materials under tension, compression bending, transverse and shear loads. Hardness test on metals can also be conducted.

Principal of Operation

Operation of the machines is by hydraulic transmission of load from the test specimen to a separately housed load indicator. The hydraulic system is ideal since it replaces transmission of load through levers and knife edges, which are prone to wear and damage due to shock on rupture of test pieces. Load is applied by a hydrostatically lubricated ram. Main cylinder pressure is transmitted to the cylinder of the pendulum dynamometer system housed in the control panel. The cylinder of the dynamometer is also of self-lubricating design. The load transmitted to the cylinder of the dynamometer is transferred through a lever system to a pendulum. Displacement of the pendulum actuates the rack and pinion mechanism which operates the load indicator pointer and the autographic recorder. The deflection of the pendulum represent the absolute load applied on the test specimen. Return movement of the pendulum is effectively damped to absorb energy in the event of sudden breakage of a specimen.

Salient Features

- Most simple and Easy to use

- Able display force value and changed sharp value

- Confirms BIS 1825-1991 and ISO -7500--1986

- Able proceed tensile, compression force, peeling, tearing testing

- Auto Load Selector

- Loading Accuracy as high as +/-1%

- Straining at variable speeds to suit a wide range of materials

- Wide range of standard and special accessories, including load stabilizer

- Fully enclosed and protected pendulum

- Large effective clearance between columns enables testing of standards specimens as well as structures

NOTE : DUE TO CONSTANT R&D SPECIFICATION AND FEATURES ARE SUBJECT TO CHANGE WITHOUT NOTICE.

MOQ : 1 Set(s)

| Business Type | Manufacturer, Exporter, Supplier |

| Material | MS,SS,20MNCR5,EN8,EN36,Aluminum,Bronze |

| Color | Black |

| Shape | Square, Rectangle, Round |

| Usage | Industrial |

| Pack Type | Box |

Preferred Buyer From

| Location | Worldwide |

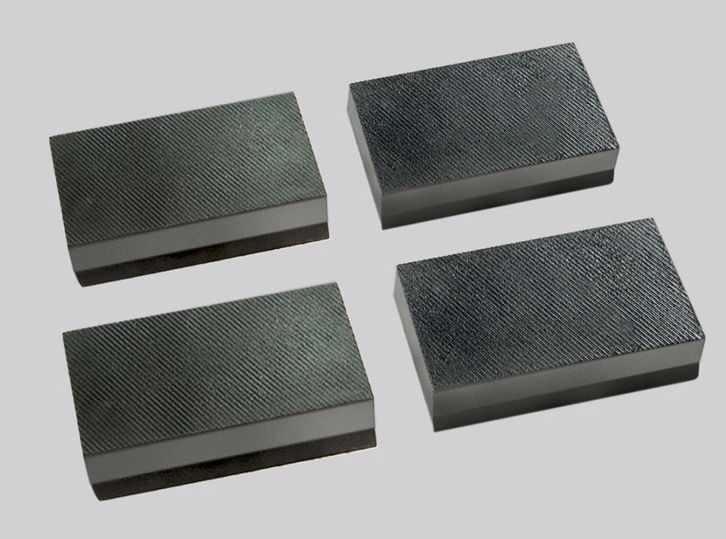

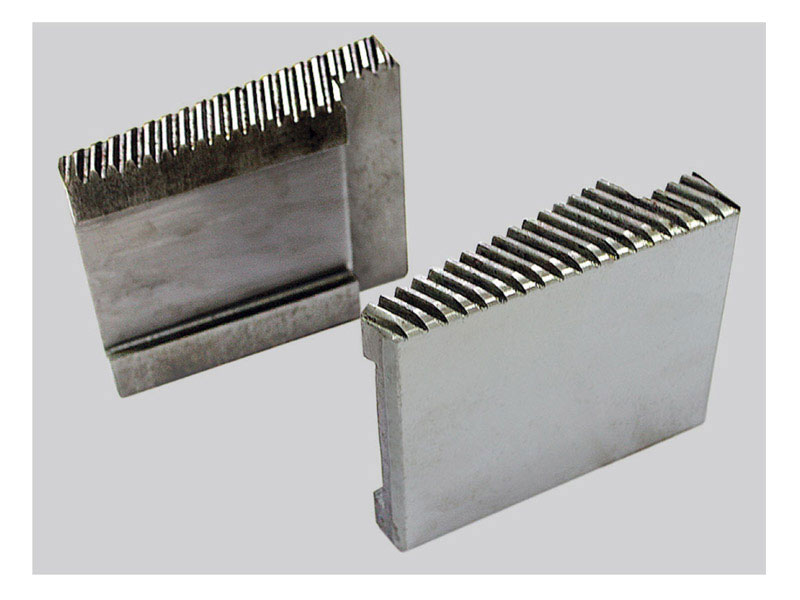

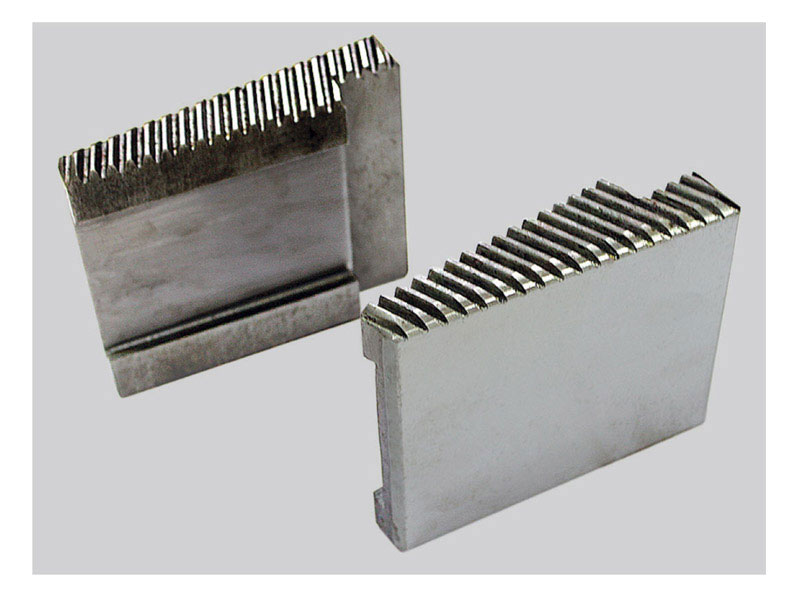

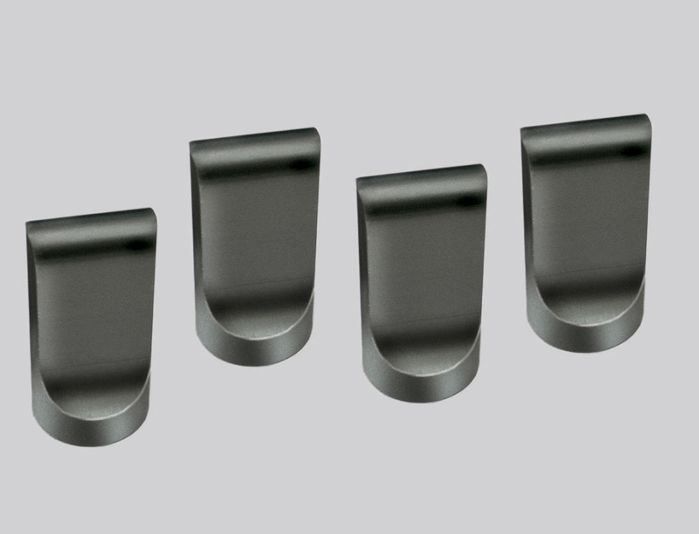

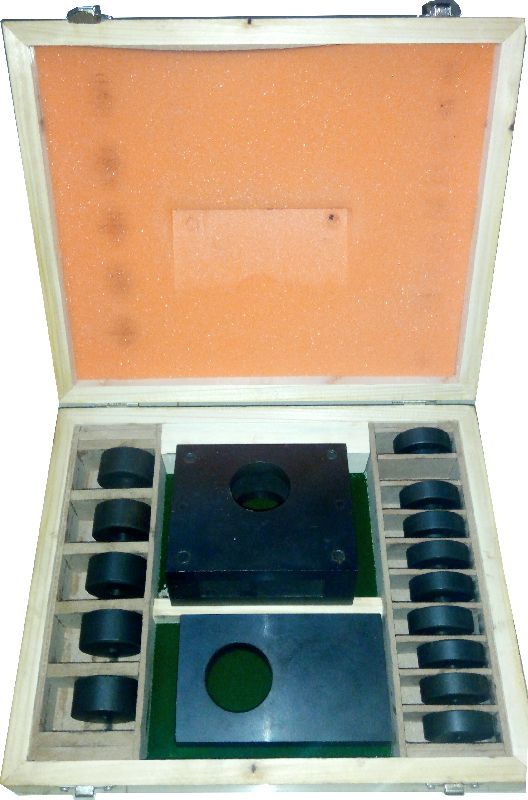

The company presents the best range of Material Testing Machine Spare Parts for the clients spread all over the world. This assortment encompasses Shoulder and Threaded Test Attachments, Universal Testing Machine Wire Rope Attachments, Universal Testing Machine Shear Test Attachments, Impact Testing Machine Combine Blocks, Testing Machine Bend and Rebend Test Attachments, Rack Jaw, Seat Jaw, Hardness Testing Blocks, Testing Extensometers, Diamond Indenters, Diamond Dresser, Poldi Test Bars. The company is a well-reckoned Material Testing Machine Spare Parts Manufacturer, Exporter, and Supplier, based in Maharashtra (India).

Universal Testing Machine Spare Parts include seat jaws, rack jacks or grips for all types of universal testing machine with capacities of 100kn, 200kn, 400kn, 600kn and 1000kn. Universal Testing Machine Spare Parts are manufactured using alloy steel and have various attributes like tensile strength, accuracy, high tolerance, good grip and no slippage. Universal Testing Machine Spare Parts are widely used in industries, foundries and laboratories.

NOTE : DUE TO CONSTANT R&D SPECIFICATION AND FEATURES ARE SUBJECT TO CHANGE WITHOUT NOTICE.

MOQ : 1 Piece

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Metal |

| Automatic Grade | Automatic |

| Application | Testing |

| Voltage | 230 Volt |

| Country of Origin | India |

| Feature | Accurate measurement |

Preferred Buyer From

| Location | Worldwide |

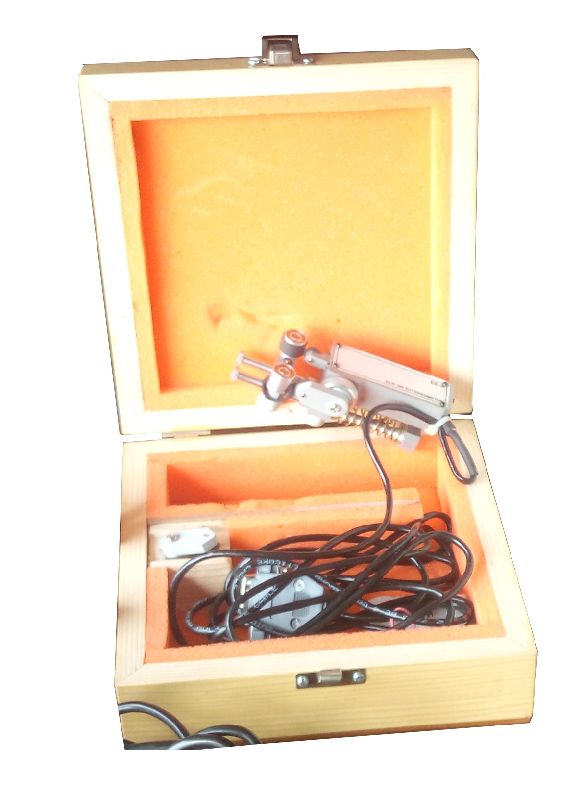

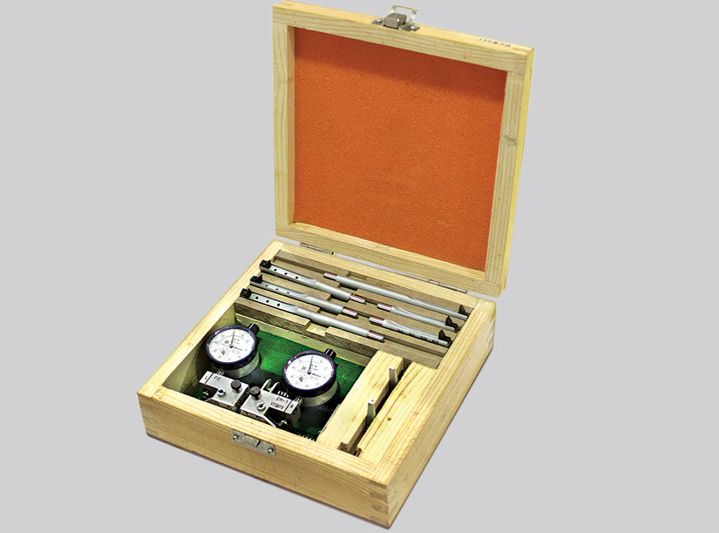

Being a well-established organization, we are engaged in providing a distinguished range of Universal Testing Conversion Machine Kit.

Conversion Kit for Converting Mechanical UTM (DIAL) to Electronic / Digital/ computerised UTM. We offer conversion kit for existing mechanical (Analogue) universal testing machine to Electronic/Digital/ computerised with Electronic Extensometer, Conversion kit includes following Data Acquisition system (Digital panel) Complete Software for UTE (Any capacity) operating through computer Pressure sensor/ Transducer Rotary Encoder Hose pipes Serial cables, connecters. Electronic Extensometer. All above conversion kit developed and manufactured by us, In the event of an order during installation our software person will also be present to complete the installation and clarify technical issues if any. Software facilities and Digital Panel features (With image) mentioned below.

Software facilities-Windows based, Menu driven software :

- Once PC connected, All operations Displays, Keys operation from PC.

- View Report, Print Report Facility. Facility to add customer’s logo in certificate.

- Load Unit Selection (kN, kg, pounds), Displacement unit (mm, inch)

- Online Graph Auto scaling. On line 2 graphs with Extensometer facility.

- Statistics include Water fall diagram for curve, Histogram, variation, Mean Deviation on selected result like Ultimate Load, Ultimate Stress, Total Elongation, % of Elongation etc. Facility to get Batch report as per selection, Facility for Sample Id, customer details

- Data bank defines facility for continuous production specimens. Here you can get statistics over long period like monthly, yearly etc.

- Facility to select different graphs. Plot load, Displacement Vs Time etc.

- Facility for Graph comparison (Compare with standard by plotting both simultaneously). Graph zoom, point tracing, selected portion zoom etc.

- Modulus data, yield calculation by method selection etc.

- Facility to select different specimen types like Round solid, Round Hollow, Rectangular, Irregular shape, TMT Bar etc.

Results with Standard Test include Ultimate Load, Displacement at ultimate Load, Maximum displacement. Ultimate stress, % Elongation, % Reduction in Area, Yield with Method selection. (If specimen doesn't have distinct yield it is recommended to use Extensometer for Yield calculation).

NOTE : DUE TO CONSTANT R&D SPECIFICATION AND FEATURES ARE SUBJECT TO CHANGE WITHOUT NOTICE.